If you love cooking, the right cutting board can make all the difference. An end grain cutting board is more than just a surface to chop on—it protects your knives and lasts longer than regular boards.

Imagine slicing through vegetables or meat with ease, without dulling your blades or damaging the board. Curious to know why this type of cutting board is a favorite among chefs and home cooks alike? Keep reading, and you’ll discover how an end grain cutting board can transform your kitchen experience.

What Is An End Grain Cutting Board

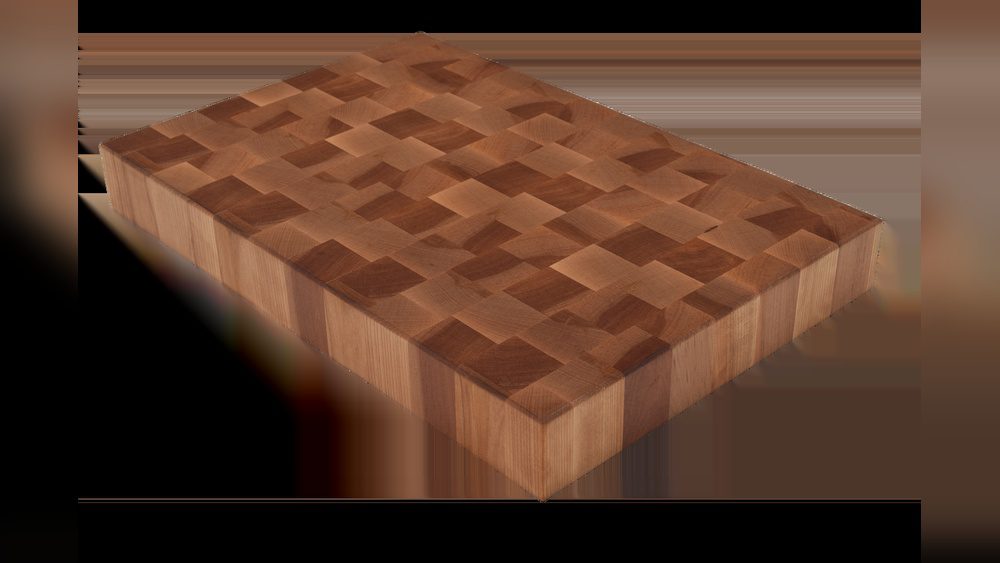

An end grain cutting board is a special type of wooden board used in kitchens. It is made by placing the wood pieces so that the ends face up. This design shows the wood’s growth rings on the surface.

This style of cutting board is different from face grain or edge grain boards. It has unique features that make it popular among cooks and chefs.

Wood blocks are cut into small pieces and arranged with the grain ends facing up. The pieces are glued and pressed together tightly. This creates a strong and durable surface for cutting.

Why Choose An End Grain Cutting Board

The surface is gentle on knives. The wood fibers absorb the blade’s impact, keeping knives sharper longer. The board also hides scratches better than other types.

Common Uses Of End Grain Cutting Boards

These boards are ideal for chopping vegetables, slicing meat, and dicing fruits. They can handle heavy use and last for many years with proper care.

Benefits Of End Grain Boards

End grain cutting boards offer many benefits that make them a popular choice in kitchens. Their unique design helps protect knives and keeps the board lasting longer. Many chefs and home cooks prefer them for daily use.

Durability And Longevity

End grain boards last longer than other types. The wood fibers stand up to cuts better. The board heals itself as the fibers close back after each cut. This means fewer deep marks and cracks over time.

Gentle On Knives

The wood fibers absorb the impact of knives. This keeps blades sharper longer. Cutting on end grain boards causes less dulling than other boards. It helps maintain knife edges without frequent sharpening.

Better Hygiene

End grain boards resist bacteria more effectively. The wood fibers close tight after cutting, reducing germs. Proper cleaning keeps the board safe and clean. It is easier to maintain hygiene with these boards.

Attractive Appearance

End grain boards show unique wood patterns. The design adds beauty to kitchens. They often become a stylish kitchen accessory. This visual appeal makes them popular gifts too.

Stable And Safe Cutting Surface

These boards stay steady during use. The thick construction prevents slipping. A stable surface means safer cutting. It reduces accidents in the kitchen.

Types Of Wood Used

End grain cutting boards are popular for their durability and beauty. The type of wood used affects the board’s strength and appearance. Different woods offer various textures, colors, and hardness levels. Choosing the right wood can make a big difference in how the board performs and lasts.

Maple

Maple is a common choice for end grain cutting boards. It has a light color and smooth grain. This wood is hard and resists cuts well. Maple is also gentle on knives, helping them stay sharp longer.

Walnut

Walnut has a rich, dark color that many find attractive. It is strong and durable, perfect for heavy use. Walnut’s natural oils help protect the board from moisture and stains.

Cherry

Cherry wood has a warm, reddish tone that deepens with time. It is moderately hard and easy to work with. Cherry boards develop a unique patina, adding character over years.

Teak

Teak is known for its natural oils and resistance to water. This makes it ideal for cutting boards. It has a golden-brown color and a tight grain that resists bacteria.

Beech

Beech is a pale wood with a fine, even grain. It is hard and durable, making it a good choice. Beech boards are affordable and maintain their shape well.

How End Grain Boards Are Made

Making an end grain cutting board is a careful process. It involves skill and attention to detail. The wood is prepared and arranged to create a strong and beautiful board. Each step adds to the board’s durability and charm.

Selecting The Wood

Wood choice is important. Hardwoods like maple, walnut, and cherry are common. These woods resist cuts and last longer. The wood must be dry and free from defects.

Cutting The Wood Into Blocks

The wood is cut into small blocks. Each block shows the grain on its end. This arrangement helps protect the knife edge and the board surface.

Arranging And Gluing The Blocks

Blocks are placed with the grain facing up. They are arranged in a pattern or random design. Wood glue holds the blocks tightly together. Clamps press the blocks until the glue dries.

Sanding And Finishing

After drying, the board is sanded smooth. This removes rough edges and glue spots. The board is then treated with food-safe oil. The oil protects the wood and enhances its color.

Durability Compared To Other Boards

End grain cutting boards are known for their strong durability. They last longer than many other types of cutting boards. The way the wood fibers are arranged helps these boards handle heavy use. This section compares the durability of end grain boards with other common boards.

Durability Of End Grain Cutting Boards

End grain boards have wood fibers standing upright. This helps the board absorb knife cuts better. The blades go between the fibers, not across them. This keeps the surface smooth and reduces deep marks. The board repairs itself as the fibers close after cutting. This means less damage over time.

Durability Of Edge Grain Cutting Boards

Edge grain boards show wood fibers running lengthwise. Knife cuts go across these fibers. This causes more visible marks and wear. Edge grain boards can develop scratches faster. They need more frequent maintenance to stay smooth. They are less forgiving to heavy chopping.

Durability Of Plastic Cutting Boards

Plastic boards are easy to clean and light. They can get deep cuts quickly. Knife marks can trap bacteria if not cleaned well. Plastic boards wear out faster than wood. They may need replacement every year or two with heavy use.

Durability Of Bamboo Cutting Boards

Bamboo boards are hard and eco-friendly. They resist scratches better than soft woods. Still, bamboo can split or crack over time. Bamboo boards need regular oiling to avoid drying out. Their durability is good but less than end grain wood.

Preventing Knife Damage

Protecting your knives is important for cooking and safety. End grain cutting boards help keep knives sharper longer. They reduce wear and tear on the blade edges. Using the right board stops damage and saves money on sharpening or replacing knives.

What Makes End Grain Boards Gentle On Knives

End grain boards show the wood fibers’ ends, not the sides. This means knife blades cut between the fibers. The fibers absorb the blade’s impact and close back after the cut. This action is softer on knives than other boards. It helps keep blades sharp and extends their life.

How To Use End Grain Boards For Best Knife Care

Cut on the flat surface of the end grain board only. Avoid chopping with heavy force or twisting motions. Use smooth, even strokes when cutting. Clean and dry the board after use to keep it stable. Store knives properly to avoid dulling even after cutting.

Other Tips To Prevent Knife Damage

Regularly sharpen knives to keep edges clean and effective. Avoid cutting on hard surfaces like glass or stone. Use separate boards for meat and vegetables to prevent cross-contamination. Replace boards that are deeply scored or cracked to protect knives from uneven surfaces.

Cleaning Tips For Longevity

Cleaning an end grain cutting board properly helps keep it strong and safe. Dirt and moisture can harm the wood if not cleaned well. Good care can extend your board’s life by years. Here are simple cleaning tips for your board’s longevity.

Wash With Warm Soapy Water

Use warm water and mild soap to clean the board after use. Avoid soaking it in water to prevent swelling. Scrub gently with a soft sponge or cloth. Rinse well and dry immediately with a towel.

Disinfect With Vinegar

Vinegar kills bacteria without harsh chemicals. Spray white vinegar on the board’s surface and let it sit for a few minutes. Wipe clean with a damp cloth. This keeps your board hygienic and safe for food.

Remove Stains With Baking Soda

Sprinkle baking soda on tough stains or odors. Use a damp cloth or sponge to scrub the area gently. Baking soda absorbs smells and lifts stains naturally. Rinse and dry the board after cleaning.

Dry Thoroughly After Cleaning

Always dry your cutting board completely after washing. Use a clean towel to remove moisture from all sides. Stand it upright to air dry fully. This stops warping and mold growth.

Regularly Oil The Board

Apply food-safe mineral oil to keep wood hydrated and prevent cracking. Rub oil into the surface with a soft cloth once a month or as needed. Let the oil soak in overnight, then wipe off excess.

Oiling And Conditioning

Oiling and conditioning an end grain cutting board keeps it strong and lasting. Wood can dry out and crack without care. Regular oiling fills the wood pores and protects the board from water damage. Conditioning adds a layer that keeps the surface smooth and safe for food.

These steps also help maintain the board’s natural beauty. A well-oiled board looks rich and clean. It also resists stains and odors better. This care routine is simple and quick but very effective.

Choosing The Right Oil

Use food-safe oils for your cutting board. Mineral oil is a popular choice. It does not go bad or turn sticky. Avoid cooking oils like olive or vegetable oil. They can spoil and cause smells. Specialized cutting board oils or beeswax blends work well too.

How To Apply Oil

Clean the board before oiling. Use a soft cloth or paper towel to spread oil evenly. Cover the whole surface and edges. Let the oil soak in for several hours or overnight. Wipe off any extra oil to avoid stickiness. Repeat the process monthly or as needed.

Conditioning With Wax

Conditioning adds extra protection after oiling. Use a beeswax and mineral oil blend. This mix seals the wood and adds shine. Rub a small amount on the board with a soft cloth. Buff it well to remove excess wax. Condition your board every few months for best results.

Avoiding Common Issues

End grain cutting boards are durable and beautiful but need care. Many users face common problems that reduce their board’s lifespan. Avoiding these issues keeps your board safe and functional for years.

Simple steps prevent damage like warping, cracking, and stains. Understanding these problems helps maintain your board’s quality and appearance.

Preventing Warping And Cracking

Keep your board dry and flat. Do not soak it in water or put it in the dishwasher. Excess water causes wood to swell and then shrink, leading to cracks.

Store the board in a cool, dry place. Avoid direct sunlight or heat sources, which can dry the wood unevenly.

Regular Oiling For Longevity

Apply food-safe mineral oil to your board often. Oil prevents the wood from drying out and keeps it strong. Without oil, the wood can split or become rough.

Rub the oil gently into the surface and let it soak overnight. Wipe off any extra oil the next day.

Cleaning Tips To Avoid Stains And Odors

Clean the board right after use with warm, soapy water. Rinse well and dry with a towel. Avoid harsh chemicals or bleach, which can damage the wood.

For odors, rub the surface with half a lemon and some salt. Rinse and dry thoroughly.

Repairing Minor Damage

End grain cutting boards are strong but can get minor damage over time. Small cuts, dents, or scratches are common. Repairing these small problems keeps the board safe and looking fresh. It also helps the board last longer.

Assessing The Damage

First, check the board carefully. Look for deep cuts or cracks. Small scratches and dents are easier to fix. Mark the areas that need attention. This step helps plan the repair work.

Sanding The Surface

Use fine-grit sandpaper to smooth the damaged spots. Sand lightly to remove rough edges and scratches. Keep the surface even with the rest of the board. Wipe away dust with a clean cloth after sanding.

Filling Small Gaps

Apply food-safe wood filler for small cracks or holes. Spread the filler smoothly with a putty knife. Let it dry fully before sanding again. This step makes the board surface flat and safe.

Oiling The Board

After repairs, oil the board to protect the wood. Use mineral oil or a special cutting board oil. Apply a thin layer and let it soak in. Oil helps prevent future damage and keeps the wood healthy.

Best Practices For Storage

Proper storage of your end grain cutting board keeps it safe and lasting longer. It helps prevent cracks, warping, and bacteria buildup. Follow these best practices to maintain its quality and hygiene.

Keep It Dry And Ventilated

Store the board in a dry place with good air flow. Avoid closed cabinets that trap moisture. Moisture causes wood to swell and crack over time.

Store Upright Or Flat

Place the board upright on its side or flat on a clean surface. Avoid leaning it against walls at an angle. This prevents warping and uneven pressure on the wood.

Avoid Direct Sunlight And Heat

Keep the board away from heat sources and direct sunlight. Heat dries out the wood quickly, causing damage. Sunlight can fade the wood’s color and texture.

Use Food-safe Oil Regularly

Apply food-safe oil before storing the board for long periods. Oil keeps the wood hydrated and seals tiny cracks. This protects the board from moisture and bacteria.

Clean Before Storing

Wash the board with mild soap and warm water after use. Dry it completely before storing. Clean boards prevent mold and bad smells from developing.

When To Replace Your Board

Knowing when to replace your end grain cutting board keeps your kitchen safe and clean. Over time, boards wear down and can harbor bacteria. Using a damaged board risks food contamination. Watch for signs that your board needs replacing. This helps protect your health and keeps your cooking area fresh.

Visible Deep Cracks Or Splits

Deep cracks trap food and bacteria. These cracks are hard to clean properly. If your board has large splits, it is time to replace it. Small cuts can be sanded out, but deep ones cannot.

Warping Or Bending

End grain boards should lie flat on the surface. Warping makes cutting unsafe and uneven. If your board no longer sits flat, consider a replacement. Warped boards can cause accidents during food preparation.

Persistent Odors

Strong, bad smells do not go away after cleaning. Odors mean bacteria have soaked into the wood. This can spoil your food and cause illness. A board with lasting smells needs to be replaced.

Surface Stains That Won’t Come Out

Stains show the board is absorbing liquids deeply. This can lead to bacteria growth inside the wood. If stains remain after thorough cleaning, replace your board. Clean surfaces are key for safe food prep.

Loose Or Broken Pieces

Check your board for loose wood pieces or splinters. These pieces can fall into your food. Broken edges also make the board unstable. Replace your board if you see wood coming apart.

Frequently Asked Questions

What Is An End Grain Cutting Board?

An end grain cutting board shows the wood’s rings on the surface. It is gentle on knives.

How Does An End Grain Board Protect Knives?

The wood fibers absorb knife cuts, keeping blades sharper longer than other boards.

Can End Grain Boards Be Used For All Types Of Food?

Yes, they are safe for cutting fruits, vegetables, meat, and bread.

How Do You Clean And Maintain An End Grain Board?

Wash with mild soap and water, dry well, and oil regularly to prevent cracking.

Why Choose An End Grain Cutting Board Over Other Boards?

End grain boards last longer and are less damaging to knives than face grain boards.

Conclusion

End grain cutting boards last longer and protect your knives well. They show less wear from chopping and stay looking nice. Easy to clean and maintain, they stay hygienic for daily use. Choosing the right board can improve your kitchen tasks.

A solid, durable board makes cooking more enjoyable and safe. Consider adding one to your kitchen tools soon. Simple, smart, and built to last.